In the domain of LPG (liquefied petroleum gas) plants, fire safety is of utmost importance. To ensure the protection of personnel, equipment, and the environment, it is crucial to implement robust firefighting systems. This article will dive into the suggested firefighting systems for LPG facilities, as outlined by industry standards such as NFPA 11, API 2510 along with other applicable guidelines.

For general fire protection – radiation exposure protection and control of burning – according to API 2510A, water is the primary means for LPG storage facilities with three primary application methods of water deluge, fixed monitors, and water spray systems ref [2]. Active fire protection systems at LPG/NGL facilities are generally designed to apply cooling water to structural members to prevent further damage and event escalation. Water applied to adjacent vessels is designed to cool the vessels to prevent a BLEVE, which has the potential to cause significant damage to the affected plant and the surrounding area ref [3].

NFPA 10 classifies fires based on the fuel involved—either type A, B, C, D, or K. Fire extinguishing agents are often identified by this system based on the type of fire for which they are effective. Among the above, class B fires are those involving flammable and combustible liquids and gases such as gasoline, crude oil, alcohols, as well as LPG ref [1].

Where the mission goes beyond the above-mentioned considerations and is set to extinguishment of the resulting fire, specific agents would be needed. To combat a class B fire, agents such as water-based foam solutions, working on the principle of cutting off fresh air and smothering the fire shall be required. These have proven to be effective for the fire class B, however, within the domain of LPG fires, special care shall be taken into account.

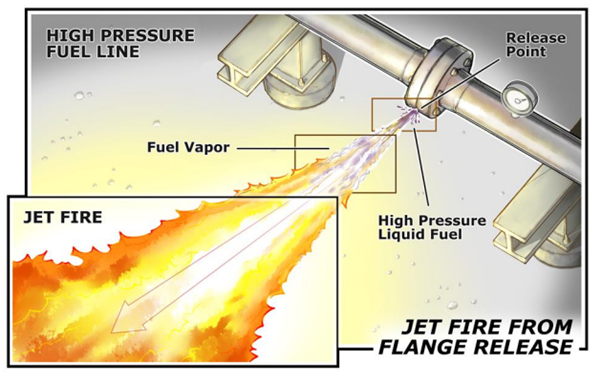

Firstly, let’s take a quick look at the two most likely fires associated with LPG which are high-pressure jet fires and liquid pool fires (see figures 1).

FIG 1 – Demonstration of Fire Development in LPG Facilities ref [3]

It is not recommended to extinguish a jet fire, as this will result in a flammable gas cloud. Additionally, water is not recommended to extinguish a pool fire because the added water will heat the LPG, increasing the vaporization rate and essentially feeding the fire.

Fire-fighting foams that are effective against common hydrocarbon liquid spill fire are ineffective against LPG fire, since the applied foam is a source of heat and promotes LPG vaporization from the refrigerated pool. For this very reason API 2510 explicitly states that “foam shall not be used” for this application ref [4]. NFPA 11, on the other hand, allows the application provided a set of requirements are met.

According to NFPA 11 by careful consideration to the resulting possibly hazardous condition, high-expansion foam can be used to control fires involving liquefied petroleum gases (LPGs) to provide vapor dispersion control. Extinguishment can occur with evolution of heavier than air vapors beneath the foam blanket. The vapors will accumulate or drain from beneath the foam blanket to low areas with the danger of vapor cloud formation or reignition or both [5]. For the foam that is used, the application rate should be in the range of 4.1 to 6.1 L/min.m2 at an expansion ratio of 500:1 in order to provide control within a few minutes. Experiments show, radiation fluxes from these fires could reduce by as much as 85 to 90 percent using high expansion foams of the specified conditions ref [6].

FIG 2 – LPG Fire Control Demonstration ref [6]

Conclusively, fire protection designer shall take into account the special characteristics of the present fuels and form their protection strategy and considered facilities, accordingly. Fire classifications are helpful but are not all that matters. Fuels special characteristics shall be reviewed as well the proper selection of active firefighting measures.

References:

[1] API RP 2001, Fire Protection in Refineries

[2] API 2510A, Fire-Protection Considerations for The Design and Operation of Liquefied Petroleum Gas (LPG) Storage Facilities

[3] Natural Gas Liquids and Liquefied Petroleum Gas Emergency Response Guide (API publications)

[4] API 2510, Design and Construction of LPG Installations

[5] NFPA 11, Standard for Low, Medium, and High-Expansion Foam

[6] Control and Extinguishment of LPG Fires, D. W. Johnson, et al.